Playground Drainage – A Crucial Investment for Play Equipment Preservation

Good drainage is crucial to the longevity and functionality of playground safety surface systems. Whether using loose-fill products, such as engineered wood fiber or rubber chips, or unitary surfaces, such as synthetic turf or poured-in-place rubber, the playground area needs proper water drainage. Most people involved in playground design and construction know the importance of moving water away from the play area. However, designers need to understand how a particular drainage system will affect the playground during and after construction.

All drainage systems are not created equal. Drainage for a playground in Las Vegas, Nevada, for example, will be different than a drainage system that's in Orlando, Florida. When in doubt, consult a local water expert who can ascertain how much drainage is needed for a particular climate and how much water, on average, will enter your playground surfacing area at any given time. For example, moving water via an entire "drain field" designed to exit into a more extensive drainage system in Orlando, Florida, makes perfect sense. In Las Vegas, such a system may be less comprehensive.

A playground area should be designed as something other than water collection points for the buildings or groundwater surrounding a playground. The accompanying photo shows water from the roof of the school building draining onto the asphalt area, which in turn drains into the playground protective area. Over half the water at this school is being discharged into the playground surfacing, rendering it unusable at certain times a year. Additionally, it can cause wood fiber displacement, premature wood rotting, and growth of insects and mold in the wood surfacing.

Solution, a sump pit inside the playground protective area is a common and economical way to address drainage concerns. A sump pit consists of a hole dug a certain length, width, and depth. The hole is then covered with a geotextile fabric and filled with drainage rock. To avoid interference with the footing layout provided by the playground equipment manufacturer, designers should show sump pits to be installed outside the fall zone to avoid interfering with play equipment footer placement.

While designers may add a slope to the play area to aid drainage, slopes greater than 1 or 2 degrees can create further problems for the installer. Unless precisely planned with the slope in mind, modular playgrounds are designed to be installed on level ground. For example, suppose there is a 2' slope in the distance of a forty-foot-long play structure with toys such as slides at opposite ends. In that case, one slide exit will be on or below ground level, while the other could be higher than 11", making both exits out of compliance.

Solution, the intentionality of the slope needs to be discussed in the design stage. Equipment designers and manufacturers can adjust for slope and even encourage equipment to be installed at different levels as part of the fun and function of the playground. Read more here.

In the late 1980s, prefabricated playground equipment was still in the infant stages. A set of plans showing a drainage design consisting of a layer of drainage rock throughout the playground protective area was not uncommon; it was widely used. However, geotextile fabric was exposed and ripped in high-traffic areas without regular surfacing maintenance, causing the drainage rock to contaminate the loose fill safety surfacing.

Additionally, a layer of drainage rock used throughout the play area can interfere with the structural integrity of the playground equipment footings. Play equipment manufacturers engineer their uprights and accompanying toys to be installed at a specific depth in native soil, not gravel or drainage rock. For example, a toy is designed to have an eighteen-inch footing, but 6" is used up in drainage rock, leaving only a 12".

This error renders the equipment out of compliance but often goes unnoticed because it is underground. It can even void the manufacturer's warranty. When the integrity of the footings is compromised, they can twist and go out of plumb, causing undue stress and premature breaking of toys. In turn, the life span of the equipment is shortened. And all because the footers were not installed in a solid footing. Think about that!

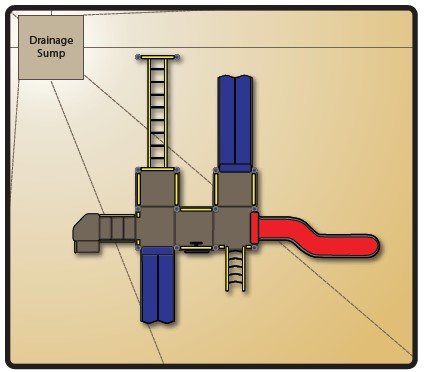

Solution, using a French drain or trench systems instead of a layer of drainage rock is now recommended. A trench that is dung along the lowest point of the playground protective area, is filled with geotextile fabric and gravel. This allows the water a place to go below grade to prevent water pooling in the playground pit.

In summary, consider the local climate and the playground equipment manufacturer's installation specs for your drainage system to perform correctly. Do not use the play area to discharge the surrounding water runoff. The goal is to move water away from the playground area without compromising the stability of the footings and manufacturer equipment height requirements.

If you have any questions please contact your LuckyDog Creative Play Designer today!